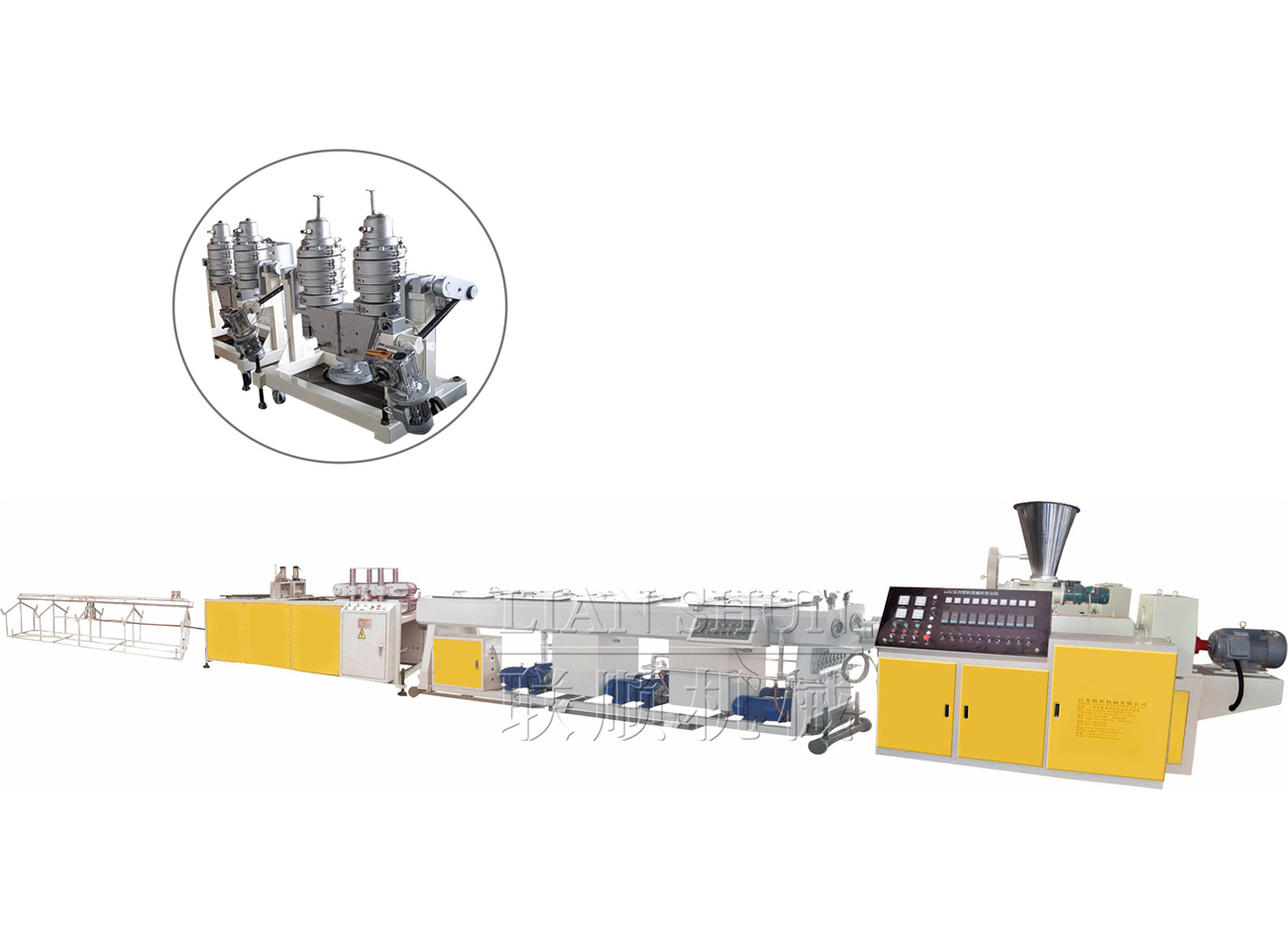

PVC Electric Conduit (double pipe) Making Machine (0.6inch-2.5inch)(DN16-63)

What is double PVC pipe machine?

Double PVC pipe machine is also called a double cavity PVC pipe extrusion production line. It is newly developed to produce two pipes at the same time. It is more like a combination of two single cavity PVC pipe machines.

Main machine is conical twin screw extruder with three models to options. Equipped with dual pipe single-control vacuum calibration tank, it avoids a waste condition if one pipe is adjusted and the other is affected. The auto single-control double puller and cutting are combined with the front shaping technology to make operation more flexible. It benefits you by separately control dual pipe extruding. The diameter of the extruded pipe is from 16mm to 63mm. it can make fully use of the extruding capacity of extruder. Even if it produces small diameter pipe, it can get higher output too.

| Extruder model | SJZ51/105 | SJZ55/120 | SJZ65/132 |

| Main motor power(kw) | 15 | 22 | 37 |

| Max. Capacity (kg/h) | 120kg/h | 150kg/h | 250kg/h |

| Diameter of pipe | 16mm - 63mm | ||

| Die head / pipe mould | Dual pipe die head | ||

| Vacuum calibration tank | dual pipe | ||

| Puller & cutting machine | Belt puller, knife cutting | ||

| Belling machine | Online belling | ||

| Usage of pipe | Water, electric conduit | ||

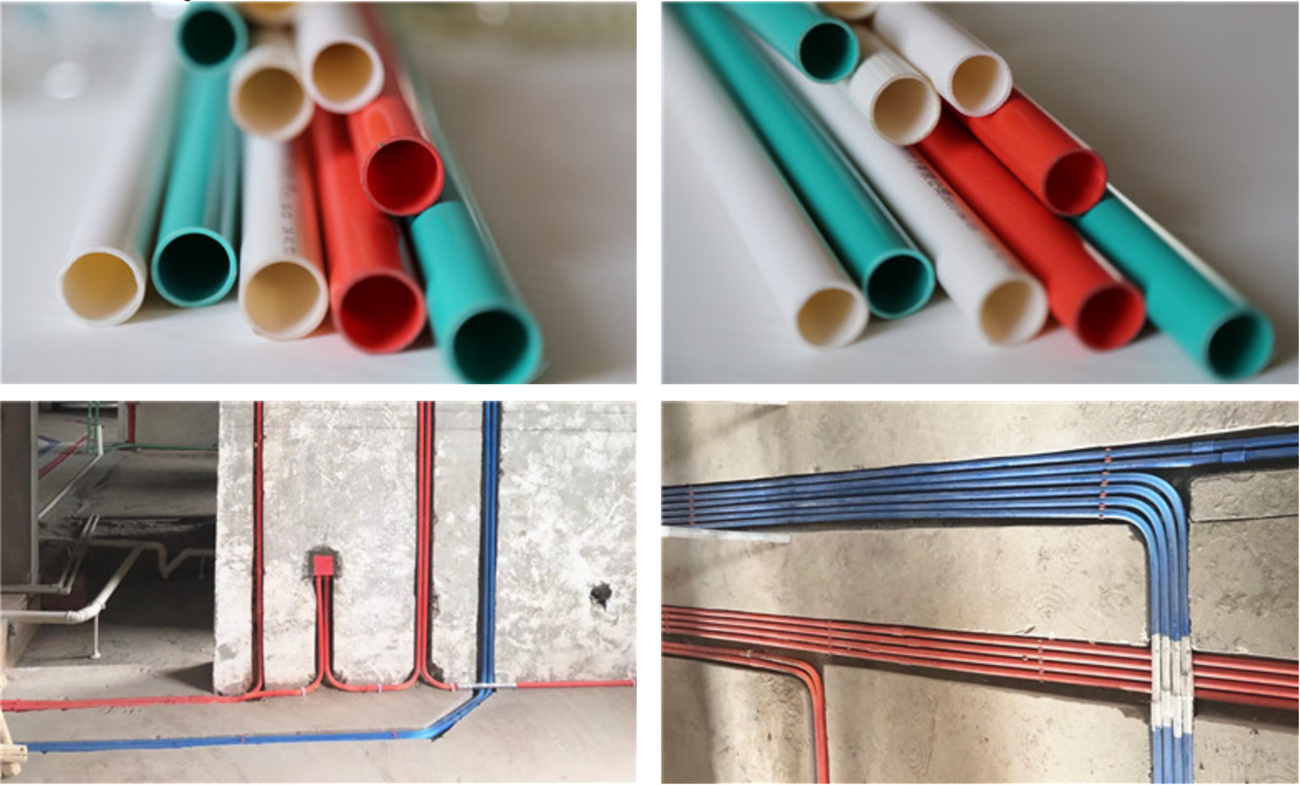

What is the application of PVC pipe extrusion machine?

Can PVC double pipe extrusion line be customized for specific pipe specifications?

Yes, as professional PVC pipe manufacturing machine supplier, we offer customization options to tailor the extrusion line to produce pipes of specific sizes, wall thicknesses, and with various additives for enhanced properties.

What is included in PVC double pipe production line?

●DTC series screw feeder

●Conical twin-screw PVC pipe extruder

●Extruder die

●Vacuum calibration tank

●PVC pipe extrusion haul-off machine

●PVC pipe cutter

●Stacker

Optional Auxiliary machines:

How is the process of PVC pipe extrusion line?

Screw Loader → Conical twin-screw extruder → Mold and calibrator → Vacuum forming machine → Cooling tank → Haul off machine → Cutting machine → Discharging Stacker

Flow Chart of PVC pipe extrusion line:

|

No |

Name |

Description |

|

1 |

Conical twin-screw PVC pipe extruder |

It is mainly used for the production of double PVC pipes. |

|

2 |

Mould/Die |

Single-layer extrusion dies or multi-layer extrusion dies can be selected to produce single-layer or multi-layer pipes. |

|

3 |

Vacuum Calibration tank |

There are single chamber or double chamber structure. Depending on the extruder output and pipe diameter, the vacuum box will have different lengths. |

|

4 |

Spray Cooling tank |

Multiple spray cooling tanks can be used to achieve better cooling effect. |

|

5 |

Haul-off and Cutter machine |

Single control double traction machine and cutting are integrated with the front double setting technology, making the operation more flexible. |

|

6 |

Stacker |

Used to collect pipes |

|

Note: Machines can be customized according to customer requirements. Our company make the most suitable machine configuration according to customer requirements. |

||