Plastic Extruders

What is Plastic Extruder?

Plastic Extruder means material hopped from hopper to screw, transported, gradually melted by the mechanical energy generated by turning screws, slowly turned from solid particles to high plastic, and then slowly became a viscous fluid (viscosity) then persistently squeeze.

Types of Plastic Extruder Machine

Single Screw Extruder

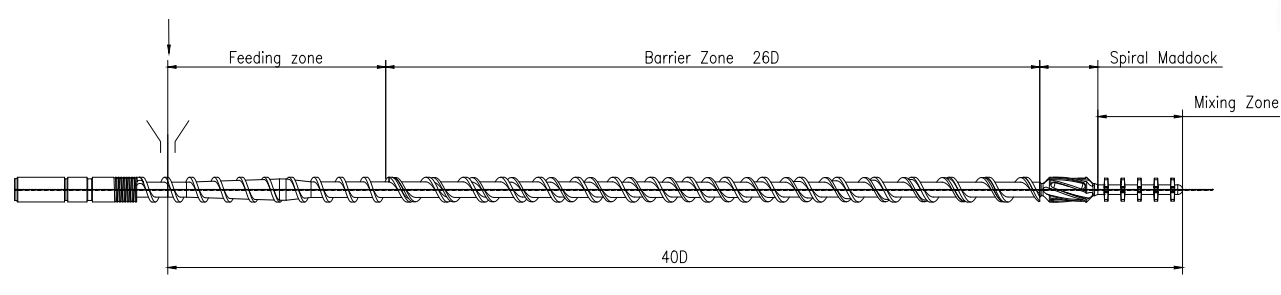

The optimum barrier screw is applicable for a wide range of raw materials and articles. The precise temperature control system ensures the constant and stable output under different speeds. The specially designed groove feeding barrel suits the screw structure and ensures the steady and reliable production. The powerful and durable dynamic driving guarantees stable extrusion volume and superior article quality. The high-performance co extruder machine could either be controlled independently or tandem drive controlled with the main extruder.

Screw: high output, wear-resistant design, even & smooth melting, gentle melting process, low melt temperature

Barrel: high quality steel alloy

Motor: efficient and energy-saving motor (AC/DC motor)

Reliable gearbox: long service life, low maintenance cost

Quality electrical components: world famous brand, stable and reliable

Gravim etric dosing control system: accurate control on weight per meter, raw material saving

Control system: auto control on whole line, real-time data logging

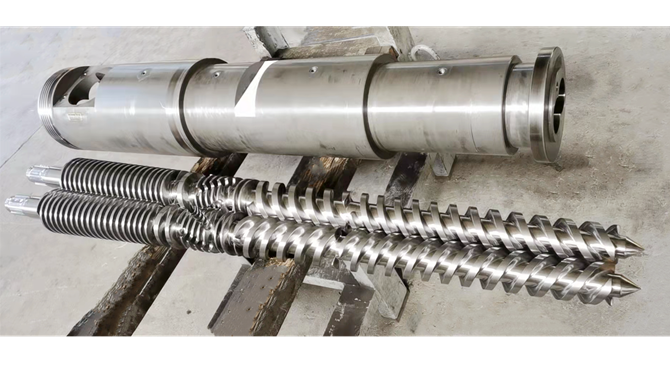

Conical Twin Screw Extruder

The longer screw with the newest double conical structure and variable pitch improves the output by over 30%. The compact distribution gearbox with the thrust bearings of the famous brand makes the convenient assembly and/or disassembly. The hardened gear surface of the gearbox guarantees the high loading capacity and long service life. The extruder and feeder are driven by the DC motor. The using of DC speed controller achieves the synchronization of the extruder, feeder and haul-off machine, which makes operation more convenient. The Japanese RKC meter ensures precise temperature controlling. The main electric components are from the overseas suppliers or domestic joint ventures. The melt pressure and temperature transducers allow the obvious inspection of the melt and easy operation.

The Twin Screw Extruder are mainly used for the processing of the soft/hard PVC pipes, PVC profiles, PVC cables, PVC transparent bottles as well as the other polyolefin products, especially the direct processing of the plastic/powder materials.

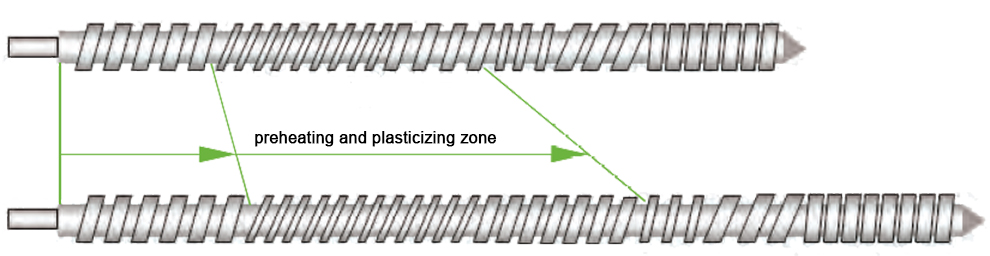

Parallel Twin Screw Extruder Machine

Optimized design of the ventilating parallel counter-rotating twin screw has advantages of low wear, low energy consumption, high efficiency, and uniform stability extrusion. Professional brand of gearbox for parallel twin screw, stable, durable and low maintenance costs.

Siemens control system guarantees automatic control of the whole line.

High quality electrical components ensure reliable control accuracy and service life.

Excellent temperature control system guarantees temperature control precision of each heating zone of extruder, thus ensuring good quality of products.

A good vacuum exhaust system ensures the pumping and dehumidifying effect during extrusion process.

The well-structure water-cooled, air-cooled system on barrel ensures good product quality.

Screw: high output, wear-resistant design

Barrel: high quality steel alloy, nitrogen treatment wearing resistance

Motor: efficient and energy-saving motor (AC/DC motor)

Reliable gearbox: long service life, reliable and durable

Quality electrical components: world famous brand, stable and reliable

Raw material hopper including blender & twin screw feeding guarantees raw material continuous feeding.

Control system: auto control on whole line, real-time data logging