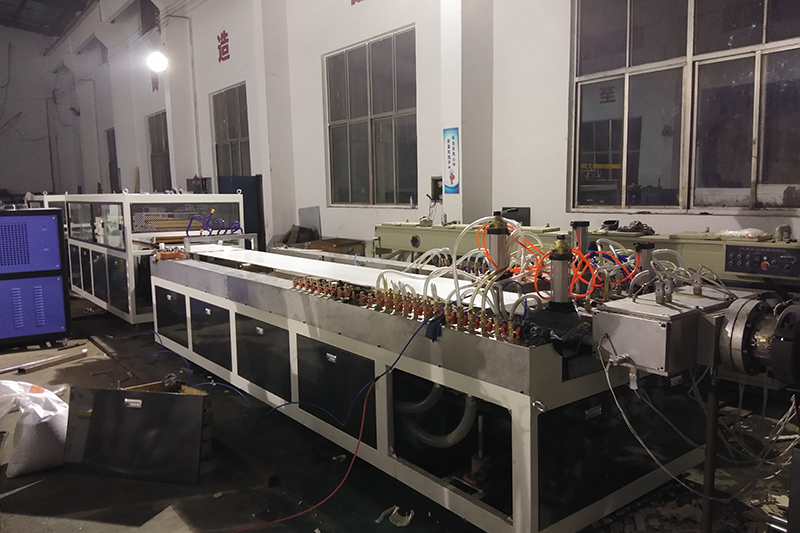

High Output PVC(PE PP) and Wood Panel Extrusion Line

Application

WPC wall panel board production line are used to WPC products, such as door, panel, board and so on. WPC products have undecomposable, deformation free, insect damage resistant, good fireproof performance, crack resistant, and maintenance free etc.

Process Flow

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mold → Calibration Table→ Haul off machine→ Cutter machine→ Tripping Table → Final Product Inspecting &Packing

Details

Conical Twin Screw Extruder

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce wpc. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

Mold

Extrusion die head channel is after heat treatment, mirror polishing and chroming to ensure material flow smoothly.

High-speed cooling forming die supports the production line with faster linear speed and higher efficiency;

. High melt homogenity

. Low pressure built up even with high outputs

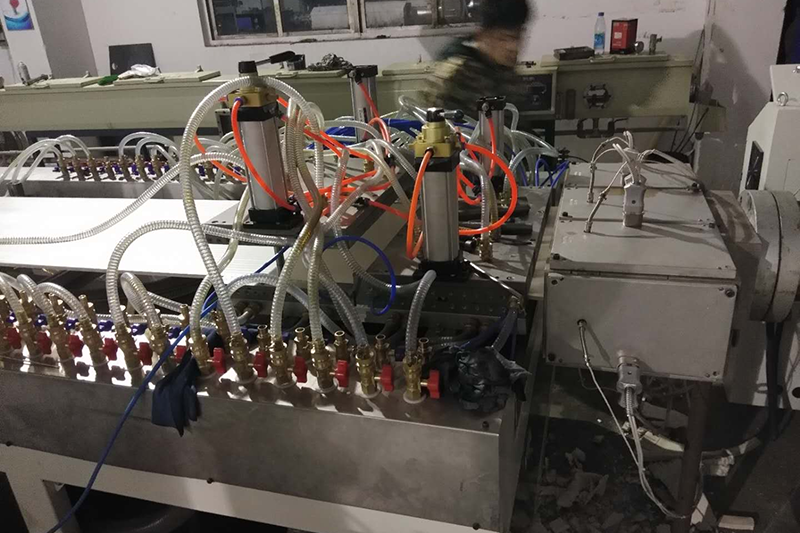

Calibration Table

Calibration table is adjustable by fore-back, left-right, up-down which brings simplified and convenient operation;

• Include full set of vacuum and water pump

• Independent operation panel for easy operation

Haul off machine

Each claw has its own traction motor, in case when one traction motor stop working, other motors can still work. It choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Claw Adjustment Device

All claws are connected to each other, when adjusting position of claws to pull pipe in different sizes, all claws will move together. This will make operation faster and easier.

Each claw with it own air pressure control, more accurate, operation is easier.

Cutter machine

Saw cutting unit brings speedy and stable cutting with smooth incision. We also offer hauling and cutting combined unit which is a more compact and economical design.

Tracking cutter or lifting saw cutter adopts double station dust collection system; synchronous driving by air cylinder or servo motor control.

Technical Data

| Model | YF600 | YF800 | YF1000 | YF1250 |

| Width of Product (mm) | 600 | 800 | 1000 | 1250 |

| Extruder Model | SJZ80/156 | SJZ80/156 | SJZ92/188 | SJZ92/188 |

| Extruder Power(kw) | 55 | 55 | 132 | 132 |

| Max of Extrusion Capacity(kg/h) | 280 | 280 | 600 | 600 |

| Cooling Water(m³/h) | 10 | 12 | 15 | 18 |

| Compressed Ail(m³/min) | 0.6 | 0.8 | 1 | 1.2 |