PVC WPC pelletizer machine Price

Description

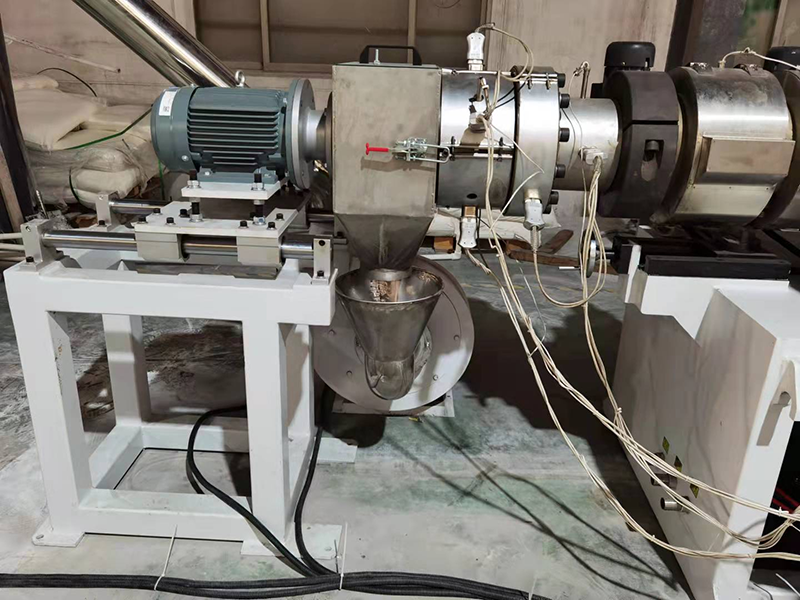

PVC pelletizing machine also called PVC pelletizer machine is mainly used for both recycled and virgin PVC pellets production,the finished pellets are beautiful. PVC pelletizing machine is easy to install and operate, mainly used in hot-cutting PVC and wood plastic granulation, etc.

Details

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

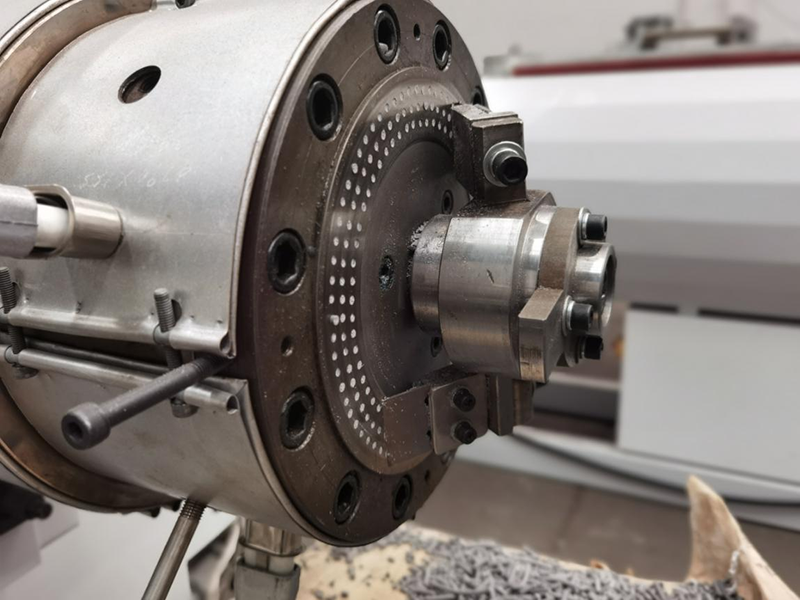

Die Head/Mold

Mold durable with high quality carbon steel material and chrome plated treatment

Reasonable flow outlet distribution ensures uniform extrusion without material interacting filtration solution.

Pelletizer

Precision blades ensure the smooth section. Imported inverter achieved requirement for different pelletizing speed.

Vibrator (Optional)

PVC granules are filtered and graded through inertia vibrator.

Cooling Device

Unique three-dimensional cooling structure, higher cooling efficiency

Multiple powerful fans combined with new cooling ideas, guarantee the quality of granules.

Technical Data

| Model | screw speed | host power | heating power | send motor power | cuting motor power | production capacity | cutter diameter | granulation size | center height |

| SJSZ51/105 | 5-40 | 18.5 | 15 | 2.2 | 1.1 | 120-180 | 200 | φ3×3 | 1000 |

| SJSZ55/110 | 5-38 | 22 | 18 | 2.2 | 1.1 | 150-200 | 200 | φ3×3 | 1000 |

| SJSZ65/132 | 5-36 | 37 | 24 | 3 | 1.5 | 150-250 | 250 | φ4×4 | 1000 |

| SJSZ80/156 | 5-34 | 55 | 36 | 4 | 2.2 | 250-450 | 280 | φ4×4 | 1000 |

| SJSZ92/188 | 5-33 | 90 | 87 | 4 | 2.2 | 500-700 | 320 | φ5×4 | 1000 |