High Output PVC Crust Foam Board Extrusion Line

Application

PVC Crust Foam board production line are used to WPC products, such as door, panel, board and so on. WPC products have undecomposable, deformation free, insect damage resistant, good fireproof performance, crack resistant, and maintenance free etc. Ma

Process Flow

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mold → Calibration Table→ Cooling tray→ Haul off machine→ Cutter machine→ Tripping Table → Final Product Inspecting &Packing

Details

Conical Twin Screw Extruder

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

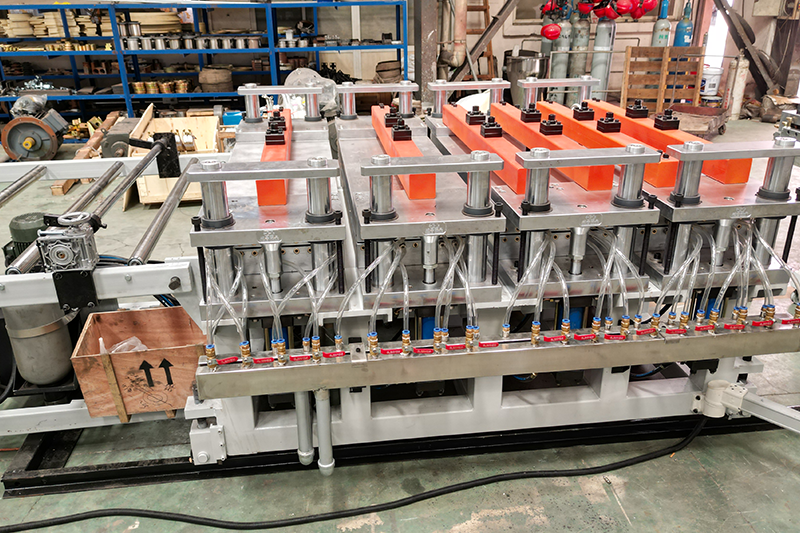

Calibration Table

Calibration table is adjustable by fore-back, left-right, up-down which brings simplified and convenient operation;

• Include full set of vacuum and water pump

• Independent operation panel for easy operation

Cooling tray

Roller Aluminum roller, surface anodized, polished, no seizure

Haul off and Cutter

The number of rubber rollers The thickness of the rubber layer of the roller bread is ≥15mm

Saw cutting unit brings speedy and stable cutting with smooth incision. We also offer hauling and cutting combined unit which is a more compact and economical design.

Tracking cutter or lifting saw cutter adopts double station dust collection system; synchronous driving by air cylinder or servo motor control.

Technical Data

| ITEM | SJSZ 51/105 | SJSZ65/132 | SJSZ 80/156 | SJSZ 92/188 |

| SCREW DIAMETERS(mm) | 51MM/105MM | 65MM/132MM | 80MM/156MM | 92MM/188MM |

| OUTPUT(kg/h) | 80-120 | 160-200 | 250-350 | 400-500 |

| MAIN DRIVING POWER(kw) | 18.5 | 37 | 55 | 90 |

| HEATING POWDER(kw) | 3 ZONES, 18KW | 4 ZONES, 20KW | 5 ZONES,38KW | 6 ZONES, 54KW |