High Output Wood Plastic Profile Extrusion Line

Application

Wood Plastic Composite machine also named wood plastic machinery, wpc machine, wpc production line, wpc extrusion machine, wpc manufacturing machine, wpc profile machine, wpc profile production line, wpc profile extrusion line and so on.

Process Flow

PE PP wood plastic:

PE/PP pallets + wood powder + other additives (used to produce exterior decorative building materials)

Production process: Wood milling (wood powder, rice, husk) —— Mixer (plastic + wood powder) ——Pelletizing machine——PE PP wood plastic extrusion line

PVC wood plastic:

PVC powder + wood powder+ other additives (used to produce interior decorative building materials)

Production process: Wood milling (wood powder, rice, husk) ——Mixer (plastic + wood powder) ——PVC wood plastic extrusion line

Advantages

1. The barrel is heated with an aluminum casting ring, and the infrared heating and air-cooling system is cooled, and the heat transfer is fast and uniform.

2. Different screws can be selected according to different formulations to achieve the best plasticization effect.

3. The replacement box, the distribution box adopts special bearing, imported oil seal, and gears using high-quality alloy steel, nitriding treatment.

4. Special design of the gearbox, distribution box, reinforced the thrust bearing, high drive torque, long service life.

5. Vacuum molding table adopts special to increase the vortex current cooling system, which is convenient for cooling, and special horizontal tilt controls unique three-position adjustment control, making it easy to operate better.

6. The tractor adopts unique lift technology, up and down track back pressure control, smooth work, large reliability, large traction, automatic cutting, and dust recovery unit.

Details

Conical Twin Screw Extruder

With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity. Different screws can be selected according to different formulations to achieve the best plasticization effect.

Mold

Extrusion die head channel is after heat treatment, mirror polishing and chroming to ensure material flow smoothly.

High-speed cooling forming die supports the production line with faster linear speed and higher efficiency;

. High melt homogenity

. Low pressure built up even with high outputs

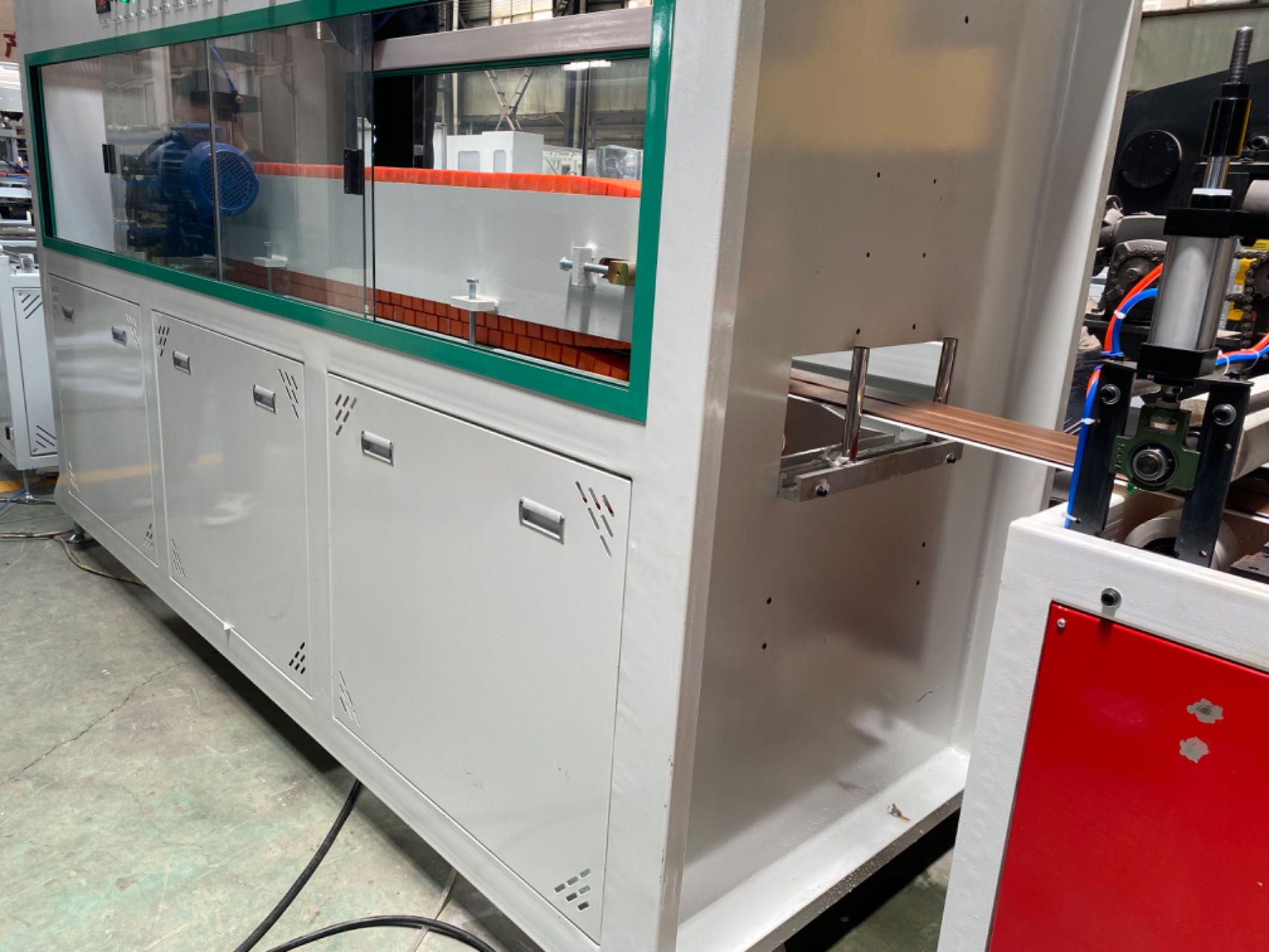

Calibration Table

Calibration table is adjustable by fore-back, left-right, up-down which brings simplified and convenient operation;

• Include full set of vacuum and water pump

• Length from 4m-11.5m;

• Independent operation panel for easy operation

Haul off machine

Each claw has its own traction motor, in case when one traction motor stop working, other motors can still work. Can choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Each claw with it own air pressure control, more accurate, operation is easier.

Cutter machine

Saw cutting unit brings speedy and stable cutting with smooth incision. We also offer hauling and cutting combined unit which is a more compact and economical design.

Tracking cutter or lifting saw cutter adopts double station dust collection system; synchronous driving by air cylinder or servo motor control.

Technical Data

| Model | SJZ51 | SJZ55 | SJZ65 | SJZ80 |

| Extruder model | Ф51/105 | Ф55/110 | Ф65/132 | Ф80/156 |

| Main moror power(kw) | 18 | 22 | 37 | 55 |

| Capacity(kg) | 80-100 | 100-150 | 180-300 | 160-250 |

| Production width | 150mm | 300mm | 400mm | 700mm |